Preventive Maintenance Scheduler

Machine breakdowns can have adverse negative impact on productivity, leading to huge losses. It’s cardinal that Industries are well prepared to stay up and running 24×7. Preventive Maintenance is the key to achieving this. It can be defined as a proactive maintenance routine, which is periodically carried out whilst the equipment/instrument is still running. This helps reduce the chance of Machine Failure. At Shel Automation we understand the importance of implementing Preventive Maintenance routine, thus we have made it an integral part of our systems. All Our new systems include a feature called “Preventive Maintenance Scheduler”. This feature notifies the user periodically about Instruments / equipment that are due for maintenance.

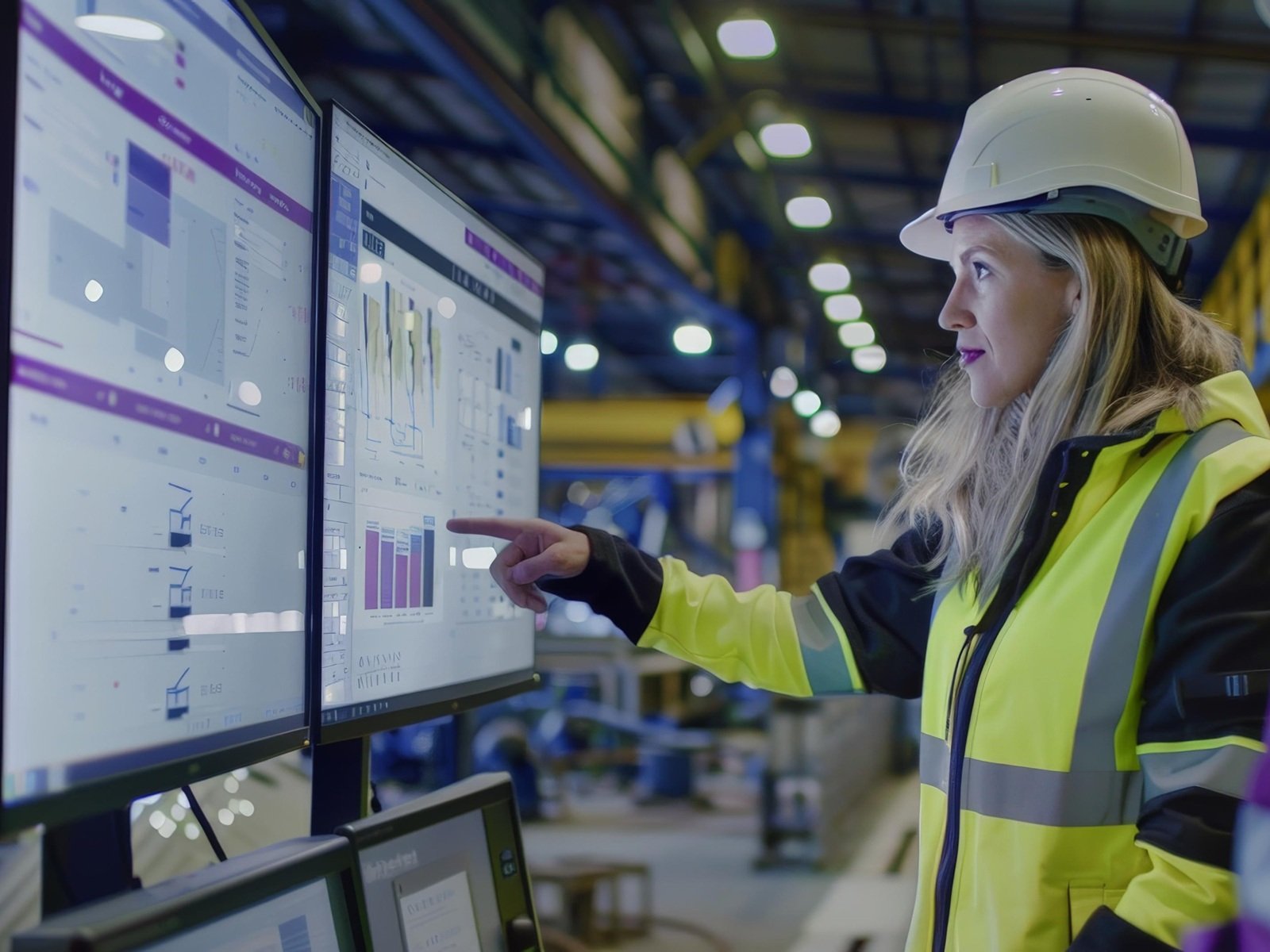

Periodic on-site checks

Our Site Engineers periodically examine all components of the automation system to identify any signs of wear, damage, or malfunction.

Control Panel Conditioning

We conduct periodic cleaning and heat scanning of control panels

Lifecycle assessment

We understand the current lifecycle status of the products in use at your site and advice the best time to replace them.

Spare Part Management

We Acquire and maintain the inventory levels necessary for optimal plant performance. Whether stored on your premises or in a central inventory, your critical parts are always available when you need them.

Software Management

We make sure that all software backups are up to date and keep record of every update or modification performed in the system programs.

Onsite Assistance

Fast and responsive onsite assistance to resolve major breakdowns.

Remote Assistance

24×7 immediate remote assistance to resolve minor untimely issues

Explore more Services

Specially Crafted Services

Experience-driven services, crafted to align with your requirements.

Upgrading your PLC system is a strategic move that can improve not just your operational efficiency, but also enhance safety, scalability and future-proof your automation systems. Our team of expert engineers can...

Our Energy Monitoring System (EMS) is a comprehensive solution designed to optimize energy usage in industrial plants. By continuously tracking energy consumption across various equipment and processes, the system provides real-time insights...