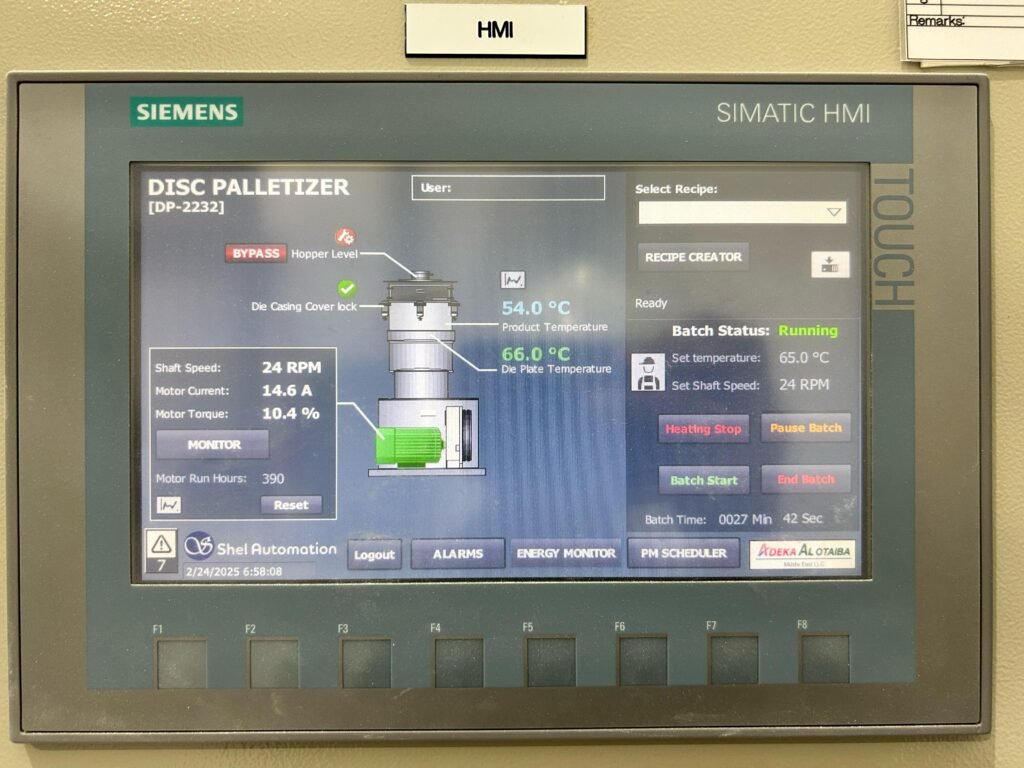

Project Name

Disc Pelletizer Automation

Industry Sector

Polymer Additives

Products & Services

- Siemens Simatic S7-1200 PLC

- Siemens KTP900 HMI

- Delta ASDA-A3 Servo System

- Control Panel Designing

Client Expectation :

The client aimed to revamp the manual control setup of their Disc Pelletizer system, transitioning to a more automated and digitized system. The key requirements included: –

- Integration of the latest PLC and HMI technology.

- Enhanced temperature control reliability for the Disc Unit.

- Digital control of the Mechanical Speed Regulator via a Servo Motor.

- Complete field cabling installation.

- Preventive maintenance scheduling and notifications within the HMI.

- Energy monitoring capabilities.

- Recipe management functionality. The project had a completion deadline of 2 months, with a maximum of 1 week allocated for shutdown.

Project Highlights

Energy Monitoring

Understanding and controlling energy consumption is key to identify areas for optimization and save energy. We integrated Energy Monitoring capabilities into our system with a dedicated page for Power data analysis.

Preventive Maintenance

Scheduling

Our system included a feature called “Preventive Maintenance Scheduling”. This feature notifies the user periodically about equipment that are due for maintenance.

Project Summary :

Customized automation solution developed after reviewing client data.

Control panel designed and built in 25 days; FAT conducted in Dubai.

Used Siemens S7-1200 PLC and KTP900 HMI.

PID loop tuned for precise Disc Unit temperature control.

Included interlocks, access restrictions, alarm logs, trends, and preventive maintenance features.

Enabled digital speed control via Servo System.

Added Energy Monitoring with data filtration.

Successfully commissioned with full client training and documentation.